PRESSURE DIFFERENCE TEST

Do you have any question ?

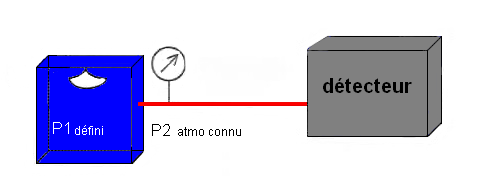

The pressure difference test is used to know a possible total or partial leakage of the part.

Localization is not an option with this test.

OPERATION:

a) A detector is connected and linked directly to the part

b) The part is filled with air at a defined pressure

c) The part lets air escape through any leaks (if there are any)

d) The detector measures the difference in pressure in the part compared to the filling pressure after a certain time.

1. If the pressure drops = the part is leaking

2. If the pressure is stable = the part is good

Pressure difference leak testing machines :

Testing bladders for molding carbon bicycle rims

• Manual product connection

• At the end of the test, the product is evacuated to facilitate packaging.

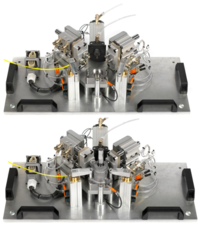

Automatic tools for leak detector, automotive sector

The tools complement the waterproofing control machines. We make tools such as:

Automatic connection tool for an aluminum foundry part.

The part can be placed by an operator or by a robot.

The part is holded, connected and plugged automatically

At the end of the test, depending on the result, the part can be marked (punching, painting, micro-percussions, laser, etc.)

Leak detector and marking